<bdo id='0ybv8'></bdo><ul id='0ybv8'></ul>

不銹鋼電動球閥是使用(yong)電能(neng)(neng)作(zuo)為(wei)動(dong)力來(lai)接通(tong)(tong)電動(dong)執行(xing)機構驅(qu)動(dong)閥(fa)(fa)桿帶動(dong)球(qiu)(qiu)(qiu)(qiu)體(ti)轉動(dong),從(cong)而實(shi)(shi)現(xian)對管道(dao)內介(jie)質的(de)流(liu)通(tong)(tong)、切斷或改(gai)變物料(liao)流(liu)通(tong)(tong)的(de)截面積,其閥(fa)(fa)體(ti)、球(qiu)(qiu)(qiu)(qiu)體(ti)、閥(fa)(fa)桿及金屬(shu)閥(fa)(fa)座(zuo)等零部件(jian)均采(cai)用(yong)不(bu)銹鋼材質制(zhi)(zhi)作(zuo),因此(ci),特(te)適用(yong)于(yu)介(jie)質溫(wen)(wen)度為(wei)-196℃~-40℃的(de)低溫(wen)(wen)工況及酸、堿、鹽等腐蝕性物料(liao)。該閥(fa)(fa)電動(dong)執行(xing)器(qi)(qi)按控制(zhi)(zhi)方式分為(wei)開(kai)(kai)關(guan)(guan)型(xing)和調節型(xing),按工作(zuo)環境(jing)有常規型(xing)和隔爆型(xing)兩種,其球(qiu)(qiu)(qiu)(qiu)體(ti)通(tong)(tong)過閥(fa)(fa)桿與(yu)電裝相連,電動(dong)執行(xing)器(qi)(qi)接入(ru)電源后(hou),按照控制(zhi)(zhi)信號(hao)改(gai)變閥(fa)(fa)內球(qiu)(qiu)(qiu)(qiu)形體(ti)的(de)位置(zhi),當球(qiu)(qiu)(qiu)(qiu)內的(de)通(tong)(tong)孔(kong)與(yu)管線通(tong)(tong)道(dao)重合(he)時(shi),閥(fa)(fa)門(men)處于(yu)開(kai)(kai)啟(qi)狀態(tai),當球(qiu)(qiu)(qiu)(qiu)內的(de)通(tong)(tong)孔(kong)與(yu)管線通(tong)(tong)道(dao)垂(chui)直(zhi)時(shi),閥(fa)(fa)門(men)處于(yu)關(guan)(guan)閉狀態(tai),當調節圓球(qiu)(qiu)(qiu)(qiu)孔(kong)道(dao)的(de)開(kai)(kai)口程度,就(jiu)能(neng)(neng)控制(zhi)(zhi)流(liu)體(ti)的(de)流(liu)量。本(ben)產品(pin)便于(yu)實(shi)(shi)現(xian)遠距(ju)離集中控制(zhi)(zhi),具有使用(yong)時(shi)間(jian)長、啟(qi)閉方便、無泄漏等特(te)點(dian)。

| 序號 | 部件名稱 | 材料名稱 | ||||

| 1 | 閥 體 | A351 CF8 | A351 CF3 | A351 CF8M | A351 CF3M | A351 CF8C |

| 2 | 閥 體 蓋 | A351 CF8 | A351 CF3 | A351 CF8M | A351 CF3M | A351 CF8C |

| 3 | 閥 座 | R-PTFE、PTFE、TEFLON、NYLON、PPL、PEEK、DEVLON、SS+HF | ||||

| 4 | 球 體 | A182 F304 | A182 F304L | A182 F316 | A182 F316L | A182 F347 |

| 5 | 閥 桿 | A182 F304 | A182 F304L | A182 F316 | A182 F316L | A182 F347 |

| 6 | 止推軸承 | PTFE | PTFE | PTFE | PTFE | PTFE |

| 7 | 止推墊片 | VITON、PTFE、NYLON、METAL+GRAPHITE | ||||

| 8 | 填 料 | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE |

| 9 | 填料壓蓋 | A351 CF8 | A351 CF8 | A351 CF8M | A351 CF8M | A351 CF8M |

| 公稱壓力Class | 150 | 300 | 600 | 900 | 1500 |

| 殼體試驗壓力(MPa) | 3.0 | 7.5 | 16.5 | 22.5 | 39.2 |

| 高壓密封試驗壓力(MPa) | 2.2 | 5.5 | 12.1 | 16.5 | 28.6 |

| 低壓密封試驗壓力(MPa) | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 |

| 電源電壓 | 單相AC220V、三相AC380V、遠程DC24V (50Hz) | ||||

| 設計制造 | ASME B16.34-2013、API 608-2008、API 6D-2014 | ||||

| 結構長度 | ASME B16.10-2017、API 6D-2014 | ||||

| 連接法蘭 | ASME B16.5-2017、ASME B16.47-2017、ANSI B16.5-2013等 | ||||

| 檢驗試驗 | API 598-2016、API 6D-2014 | ||||

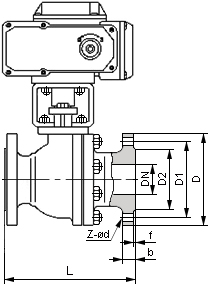

| 公稱壓力 Class | 公稱尺寸 NPS | 外形及連接尺寸/mm | |||||

| L | D | D1 | D2 | b-f | Z-?d | ||

| 150 | ? | 108 | 90 | 60.3 | 34.9 | 9.6-1.6 | 4-16 |

| ? | 117 | 100 | 69.9 | 42.9 | 11.2-1.6 | 4-16 | |

| 1 | 127 | 110 | 79.4 | 50.8 | 12.7-1.6 | 4-16 | |

| 1 ? | 140 | 115 | 88.9 | 63.5 | 14.3-1.6 | 4-16 | |

| 1 ? | 165 | 125 | 98.4 | 73.0 | 15.9-1.6 | 4-16 | |

| 2 | 178 | 150 | 120.7 | 92.1 | 17.5-1.6 | 4-19 | |

| 3 | 203 | 190 | 152.4 | 127.0 | 22.3-1.6 | 4-19 | |

| 4 | 229 | 230 | 190.5 | 157.2 | 22.3-1.6 | 8-19 | |

| 6 | 394 | 280 | 241.3 | 215.9 | 23.9-1.6 | 8-22.5 | |

| 8 | 457 | 345 | 298.5 | 269.9 | 27.0-1.6 | 8-22.5 | |

| 表中未列出的其他規格參數,請咨詢汗越閥門技術部! | |||||||

如果你需訂購我廠電動球閥產品(pin),咨詢時(shi)煩請說明結(jie)構(gou)形(xing)式(shi)、公(gong)(gong)稱壓力、公(gong)(gong)稱通(tong)徑、閥體和(he)(he)內件材料(liao)、使用介(jie)質、工(gong)作(zuo)溫度、端部連接(jie)方式(shi)等,本產品(pin)根據密封型式(shi)分為軟密封和(he)(he)金屬(shu)硬密封兩種,電動(dong)執(zhi)行機構(gou)可選用精小(xiao)型、部分回(hui)轉(zhuan)型、多回(hui)轉(zhuan)型等。