<dfn id='BYXlU'><optgroup id='jyUvS'></optgroup></dfn><tfoot id='MUcVA'><bdo id='iNB5I'><div id='8yDx2'></div><i id='HsdQ3'><dt id='MoOR7'></dt></i></bdo></tfoot>

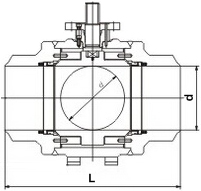

全焊接球閥是一(yi)種(zhong)具(ju)有浮動閥(fa)座,采用(yong)(yong)鋼管整(zheng)體(ti)焊接而成(cheng),適(shi)用(yong)(yong)于使(shi)(shi)用(yong)(yong)溫度為(wei)(wei)0℃~180℃,工(gong)作介質為(wei)(wei)水、蒸汽(qi)、燃(ran)(ran)氣(qi)的(de)焊接球(qiu)閥(fa),其閥(fa)體(ti)通常(chang)采用(yong)(yong)整(zheng)體(ti)鍛造制作或模(mo)壓加工(gong)成(cheng)型的(de)鋼管或板材(cai)卷制。該閥(fa)按(an)體(ti)型分為(wei)(wei)橢(tuo)圓(yuan)(yuan)形(xing)(xing)(xing)(xing)、筒(tong)形(xing)(xing)(xing)(xing)及球(qiu)形(xing)(xing)(xing)(xing)三種(zhong),橢(tuo)圓(yuan)(yuan)形(xing)(xing)(xing)(xing)的(de)閥(fa)體(ti)兩端(duan)圓(yuan)(yuan)弧(hu)(hu)形(xing)(xing)(xing)(xing)采用(yong)(yong)工(gong)裝(zhuang)冷壓成(cheng)形(xing)(xing)(xing)(xing),兩邊(bian)圓(yuan)(yuan)弧(hu)(hu)平滑過渡,減少(shao)應(ying)力(li)集中(zhong),省略(lve)了中(zhong)法蘭(lan),可以減輕(qing)(qing)閥(fa)門重(zhong)量(liang),節省制造成(cheng)本,筒(tong)形(xing)(xing)(xing)(xing)的(de)邊(bian)體(ti)為(wei)(wei)整(zheng)體(ti)鍛件,強度高,相比圓(yuan)(yuan)體(ti)能承受更大(da)的(de)管道應(ying)力(li),適(shi)用(yong)(yong)于大(da)口徑,球(qiu)形(xing)(xing)(xing)(xing)的(de)閥(fa)體(ti)結構為(wei)(wei)兩個(ge)半(ban)圓(yuan)(yuan)(弧(hu)(hu)形(xing)(xing)(xing)(xing))組成(cheng),重(zhong)量(liang)輕(qing)(qing),可以減少(shao)材(cai)料成(cheng)本,減輕(qing)(qing)管道重(zhong)量(liang)負(fu)荷,主副閥(fa)體(ti)中(zhong)部焊縫離(li)閥(fa)座位置(zhi)較遠,焊接時(shi),熱影響和變形(xing)(xing)(xing)(xing)量(liang)對閥(fa)座周(zhou)邊(bian)影響較小(xiao)。本產(chan)品具(ju)有結構簡單(dan)、免維護和使(shi)(shi)用(yong)(yong)時(shi)間長(chang)等特點,可以廣泛用(yong)(yong)于城鎮供熱系統和城市燃(ran)(ran)氣(qi)管道工(gong)程(cheng)。

| 序號 | 部件名稱 | 材料名稱 | ||||

| 1 | 閥 體 | 20# | Q345R | 06Cr19Ni10 | 06Cr17Ni12Mo2 | 022Cr17Ni12Mo2 |

| 2 | 閥 蓋 | 20# | Q345R | 06Cr19Ni10 | 06Cr17Ni12Mo2 | 022Cr17Ni12Mo2 |

| 3 | 閥 桿 | 2Cr13 | 2Cr13 | 06Cr19Ni10 | 06Cr17Ni12Mo2 | 022Cr17Ni12Mo2 |

| 4 | 球 體 | 06Cr19Ni10 | 06Cr19Ni10 | 06Cr19Ni10 | 06Cr17Ni12Mo2 | 022Cr17Ni12Mo2 |

| 5 | 密 封 圈 | VITON、R-PTFE、PTFE、TEFLON、NYLON、PPL、PEEK、DEVLON | ||||

| 6 | 填 料 | PTFE | PTFE | PTFE | PTFE | PTFE |

| 7 | 下 閥 桿 | 2Cr13 | 2Cr13 | 06Cr19Ni10 | 06Cr17Ni12Mo2 | 022Cr17Ni12Mo2 |

| 8 | 底 蓋 | Q235B | Q345R | 06Cr19Ni10 | 06Cr17Ni12Mo2 | 022Cr17Ni12Mo2 |

| 9 | 閥 管 | 20# | Q345R | 06Cr19Ni10 | 06Cr17Ni12Mo2 | 022Cr17Ni12Mo2 |

| 公稱壓力PN(MPa) | 1.6 | 2.5 | 4.0 | 6.3 | 10.0 |

| 殼體試驗壓力(MPa) | 2.4 | 3.75 | 6.0 | 9.45 | 15.0 |

| 高壓液體密封試驗壓力(MPa) | 1.76 | 2.75 | 4.4 | 6.93 | 11.0 |

| 低壓氣體密封試驗壓力(MPa) | 0.55±0.07 | 0.55±0.07 | 0.55±0.07 | 0.55±0.07 | 0.55±0.07 |

| 設計制造 | GB/T 30818、GB/T 37827、JB/T 12006、API 6D | ||||

| 結構長度 | GB/T 30818、GB/T 37827、JB/T 12006、GB/T 12221、API 6D | ||||

| 對焊端部 | GB/T 12224、GB/T 985.1~GB/T 985.2、ASME B16.25 | ||||

| 法蘭標準 | GB/T 9113、GB/T 9119、GB/T 13402、ASME B16.5、ASME B16.47 | ||||

| 檢驗試驗 | GB/T 30818、GB/T 13927、API 6D | ||||

| 公稱壓力 PN | 公稱尺寸 DN | 縮徑結構尺寸/mm | 公稱壓力 PN | 公稱尺寸 DN | 全徑結構尺寸/mm | ||

| d | L | d | L | ||||

| 16 ~ 25 | 200 | 150 | 520 | 16 ~ 25 | 200 | 201 | 635 |

| 250 | 201 | 635 | 250 | 252 | 689 | ||

| 300 | 252 | 689 | 300 | 303 | 762 | ||

| 350 | 303 | 762 | 350 | 334 | 838 | ||

| 400 | 334 | 838 | 400 | 385 | 915 | ||

| 450 | 385 | 915 | 450 | 436 | 991 | ||

| 500 | 436 | 991 | 500 | 487 | 1143 | ||

| 600 | 487 | 1143 | 600 | 589 | 1380 | ||

| 700 | 589 | 1380 | 700 | 684 | 1524 | ||

| 800 | 684 | 1524 | 800 | 779 | 1727 | ||

| 900 | 779 | 1727 | 900 | 874 | 1900 | ||

| 1000 | 874 | 1900 | 1000 | 976 | 2000 | ||

| 1200 | 976 | 2100 | 1200 | 1166 | 2430 | ||

| 1400 | 1166 | 2430 | 1400 | 1360 | 2680 | ||

| 1600 | 1458 | 2680 | 1600 | 1556 | 2950 | ||

| 表中未列出的其他規格尺寸,請咨詢汗越閥門技術部! | |||||||