不銹鋼氣動球閥由(you)氣(qi)(qi)(qi)(qi)(qi)動(dong)(dong)驅動(dong)(dong)裝置,通(tong)(tong)(tong)過控(kong)制系(xi)統控(kong)制不(bu)(bu)銹鋼球閥的啟閉,實(shi)(shi)現對管道內輸(shu)送介質(zhi)的流通(tong)(tong)(tong)或切斷,其承壓殼體和內件均采用304、304L、316、316L、321、347、310S、904L及其他(ta)不(bu)(bu)易生銹的材料鑄造(zao)(zao)或鍛(duan)造(zao)(zao)成型,因此(ci),特適用于(yu)腐蝕性、低溫或高(gao)溫介質(zhi)。該閥工作時氣(qi)(qi)(qi)(qi)(qi)源壓力從(cong)氣(qi)(qi)(qi)(qi)(qi)口a進入(ru)氣(qi)(qi)(qi)(qi)(qi)缸(gang)兩活(huo)塞(sai)之(zhi)間中腔(qiang)(qiang)時,使(shi)(shi)兩活(huo)塞(sai)分(fen)離(li)向氣(qi)(qi)(qi)(qi)(qi)缸(gang)兩端(duan)方向移動(dong)(dong),兩端(duan)氣(qi)(qi)(qi)(qi)(qi)腔(qiang)(qiang)的空氣(qi)(qi)(qi)(qi)(qi)通(tong)(tong)(tong)過氣(qi)(qi)(qi)(qi)(qi)口b排出(chu),同時使(shi)(shi)兩活(huo)塞(sai)齒(chi)條(tiao)同步(bu)帶(dai)動(dong)(dong)輸(shu)出(chu)軸逆時針方向旋轉,并通(tong)(tong)(tong)過連接套帶(dai)動(dong)(dong)閥桿轉動(dong)(dong),由(you)此(ci)打開閥門(men),反之(zhi)氣(qi)(qi)(qi)(qi)(qi)源壓力從(cong)氣(qi)(qi)(qi)(qi)(qi)口b進入(ru)氣(qi)(qi)(qi)(qi)(qi)缸(gang)兩端(duan)氣(qi)(qi)(qi)(qi)(qi)腔(qiang)(qiang)時,使(shi)(shi)兩活(huo)塞(sai)向氣(qi)(qi)(qi)(qi)(qi)缸(gang)中間方向移動(dong)(dong),中間氣(qi)(qi)(qi)(qi)(qi)腔(qiang)(qiang)的空氣(qi)(qi)(qi)(qi)(qi)通(tong)(tong)(tong)過氣(qi)(qi)(qi)(qi)(qi)口a排出(chu),則(ze)球形體反向運動(dong)(dong),關閉閥門(men)。本(ben)產品具(ju)有低流阻,便于(yu)實(shi)(shi)現遠(yuan)距離(li)控(kong)制和自動(dong)(dong)化等(deng)優(you)點(dian)。

| 序號 | 部件名稱 | 材料名稱 | ||||

| 1 | 閥 體 | A351 CF8 | A351 CF3 | A351 CF8M | A351 CF3M | A351 CF8C |

| 2 | 閥 蓋 | A351 CF8 | A351 CF3 | A351 CF8M | A351 CF3M | A351 CF8C |

| 3 | 閥 座 | R-PTFE、PTFE、TEFLON、NYLON、PPL、PEEK、DEVLON、SS+HF | ||||

| 4 | 球 體 | A182 F304 | A182 F304L | A182 F316 | A182 F316L | A182 F347 |

| 5 | 閥 桿 | A182 F304 | A182 F304L | A182 F316 | A182 F316L | A182 F347 |

| 6 | 止推軸承 | PTFE | PTFE | PTFE | PTFE | PTFE |

| 7 | 止推墊圈 | VITON、PTFE、NYLON、METAL+GRAPHITE | ||||

| 8 | 填 料 | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE |

| 9 | 填料壓蓋 | A351 CF8 | A351 CF8 | A351 CF8M | A351 CF8M | A351 CF8M |

| 公稱壓力Class | 150 | 300 | 600 | 900 | 1500 |

| 殼體試驗壓力(MPa) | 3.0 | 7.5 | 16.5 | 22.5 | 39.2 |

| 高壓密封試驗壓力(MPa) | 2.2 | 5.5 | 12.1 | 16.5 | 28.6 |

| 低壓密封試驗壓力(MPa) | 0.55±0.15 | 0.55±0.15 | 0.55±0.15 | 0.55±0.15 | 0.55±0.15 |

| 設計制造 | ASME B16.34-2013、API 608-2008、API 6D-2014 | ||||

| 結構長度 | ASME B16.10-2017、API 6D-2014 | ||||

| 法蘭標準 | ASME B16.5-2017、ASME B16.47-2017、ANSI B16.5-2013等 | ||||

| 檢驗試驗 | API 598-2016、API 6D-2014 | ||||

| 可配附件 | 信號反饋裝置、電磁閥、空氣過濾減壓閥、手動機構等 | ||||

| 氣源壓力 | 0.4MPa ~ 0.7MPa | ||||

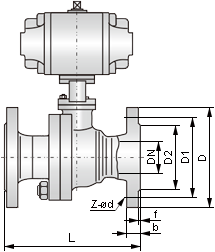

| 公稱壓力 Class | 公稱尺寸 NPS | 外形及連接尺寸/mm | |||||

| L | D | D1 | D2 | b-f | Z-?d | ||

| 150 | ? | 108 | 90 | 60.3 | 34.9 | 9.6-1.6 | 4-16 |

| ? | 117 | 100 | 69.9 | 42.9 | 11.2-1.6 | 4-16 | |

| 1 | 127 | 110 | 79.4 | 50.8 | 12.7-1.6 | 4-16 | |

| 1 ? | 140 | 115 | 88.9 | 63.5 | 14.3-1.6 | 4-16 | |

| 1 ? | 165 | 125 | 98.4 | 73.0 | 15.9-1.6 | 4-16 | |

| 2 | 178 | 150 | 120.7 | 92.1 | 17.5-1.6 | 4-19 | |

| 3 | 203 | 190 | 152.4 | 127.0 | 22.3-1.6 | 4-19 | |

| 4 | 229 | 230 | 190.5 | 157.2 | 22.3-1.6 | 8-19 | |

| 6 | 394 | 280 | 241.3 | 215.9 | 23.9-1.6 | 8-22.5 | |

| 8 | 457 | 345 | 298.5 | 269.9 | 27.0-1.6 | 8-22.5 | |

| 表中未列出的其他規格參數,請咨詢汗越閥門技術部! | |||||||

如果你需訂購我廠氣動球閥產品(pin),咨詢時煩請注明結構形式、公(gong)稱(cheng)通(tong)徑、公(gong)稱(cheng)壓(ya)力、閥體和內件材質、使用介質及(ji)工(gong)作溫度等,安裝本產品(pin)前,管道(dao)內一(yi)定要吹掃(sao),防止管道(dao)內殘留(liu)有焊渣、切削渣等,以免損傷閥座。