<bdo id='tTSrd'></bdo><ul id='xp3rZ'></ul>

氣動低溫球閥由適(shi)用(yong)(yong)(yong)(yong)(yong)于介(jie)質溫度(du)-196℃~-40℃的(de)(de)(de)(de)(de)(de)浮動(dong)(dong)球或固定(ding)球球閥(fa)與氣動(dong)(dong)執行(xing)機構組成,通過(guo)氣缸活塞(sai)角行(xing)程(cheng)控(kong)制(zhi)閥(fa)門(men)的(de)(de)(de)(de)(de)(de)啟閉(bi),其氣動(dong)(dong)執行(xing)器的(de)(de)(de)(de)(de)(de)輸(shu)出(chu)端與閥(fa)桿的(de)(de)(de)(de)(de)(de)上端之(zhi)間經連(lian)接(jie)(jie)軸傳動(dong)(dong)聯接(jie)(jie),利(li)用(yong)(yong)(yong)(yong)(yong)有(you)(you)壓氣體作為動(dong)(dong)力(li)源,推動(dong)(dong)活塞(sai)移動(dong)(dong),從而通過(guo)輸(shu)出(chu)軸驅動(dong)(dong)閥(fa)桿帶動(dong)(dong)球體旋轉,實現閥(fa)門(men)的(de)(de)(de)(de)(de)(de)開啟和關(guan)閉(bi)動(dong)(dong)作。該(gai)閥(fa)填料根據(ju)使(shi)用(yong)(yong)(yong)(yong)(yong)溫度(du)可(ke)采用(yong)(yong)(yong)(yong)(yong)PTFE、柔性石墨(mo)、唇形密封(feng)圈等(deng)多重組合的(de)(de)(de)(de)(de)(de)型式,有(you)(you)很好(hao)的(de)(de)(de)(de)(de)(de)耐低(di)溫性能,而且(qie)中法蘭密封(feng)選(xuan)用(yong)(yong)(yong)(yong)(yong)具有(you)(you)抵(di)抗溫度(du)交變、高回彈特(te)性的(de)(de)(de)(de)(de)(de)金(jin)屬(shu)纏繞柔性石墨(mo)墊(dian)片、金(jin)屬(shu)環(huan)墊(dian)。本產品(pin)氣缸通常與行(xing)程(cheng)限位開關(guan)、電磁(ci)閥(fa)、空氣過(guo)濾減壓閥(fa)等(deng)附件配套使(shi)用(yong)(yong)(yong)(yong)(yong),接(jie)(jie)入0.4 ~ 0.7MPa氣源即(ji)可(ke)控(kong)制(zhi)運(yun)轉,因此(ci)特(te)適(shi)合安裝在液化(hua)天然氣、液態乙烯(xi)、液氧、液氫等(deng)不適(shi)宜人工(gong)手(shou)動(dong)(dong)操作的(de)(de)(de)(de)(de)(de)低(di)溫介(jie)質管(guan)道上,作遠距(ju)離和自動(dong)(dong)化(hua)控(kong)制(zhi)。

| 序號 | 部件名稱 | 材料名稱 | ||||

| 1 | 閥 體 | A350 LF2 | A182 F304 | A182 F304L | A182 F316 | A182 F316L |

| 2 | 閥 蓋 | A350 LF2 | A182 F304 | A182 F304L | A182 F316 | A182 F316L |

| 3 | 閥 座 | R-PTFE、PTFE、TEFLON、PCTFE、PPL、SS+HF | ||||

| 4 | 球 體 | A350 LF2 | A182 F304 | A182 F304L | A182 F316 | A182 F316L |

| 5 | 閥 桿 | A350 LF2 | A182 F304 | A182 F304L | A182 F316 | A182 F316L |

| 6 | 固 定 軸 | A350 LF2 | A182 F304 | A182 F304L | A182 F316 | A182 F316L |

| 7 | 填 料 | GRAPHITE、R-PTFE、PTFE、TEFLON、PCTFE | ||||

| 8 | 連 接 板 | A350 LF2 | A182 F304 | A182 F304L | A182 F316 | A182 F316L |

| 9 | 隔離滴盤 | A350 LF2 | A182 F304 | A182 F304 | A182 F304 | A182 F304 |

| 公稱壓力Class | 150 | 300 | 600 | 900 | 1500 |

| 殼體試驗壓力(MPa) | 3.0 | 7.5 | 16.5 | 22.5 | 39.2 |

| 高壓液體密封試驗壓力(MPa) | 2.2 | 5.5 | 12.1 | 16.5 | 28.6 |

| 低壓氣體密封試驗壓力(MPa) | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 |

| 設計制造 | ASME B16.34-2013、API 608-2008、API 6D-2014 | ||||

| 結構長度 | ASME B16.10-2017、API 6D-2014 | ||||

| 法蘭標準 | ASME B16.5-2017、ASME B16.47-2017、ANSI B16.5-2013等 | ||||

| 檢驗試驗 | API 598-2016、API 6D-2014 | ||||

| 可配附件 | 信號反饋裝置、電磁閥、空氣過濾減壓閥、手動機構等 | ||||

| 氣源壓力 | 0.4MPa ~ 0.7MPa | ||||

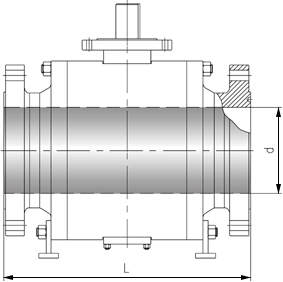

| 公稱壓力 Class | 公稱尺寸 NPS | 結構尺寸/mm | 公稱壓力 Class | 公稱尺寸 NPS | 結構尺寸/mm | ||

| d | L | d | L | ||||

| 150 | 2 | 49 | 178 | 150 | 12 | 303 | 610 |

| 2 ? | 62 | 190 | 14 | 334 | 686 | ||

| 3 | 74 | 203 | 16 | 385 | 762 | ||

| 4 | 100 | 229 | 18 | 436 | 864 | ||

| 6 | 150 | 394 | 20 | 487 | 914 | ||

| 8 | 201 | 457 | 22 | 538 | 1016 | ||

| 10 | 252 | 533 | 24 | 589 | 1067 | ||

| 表中未列出的其他規格參數,請咨詢汗越閥門技術部! | |||||||