<bdo id='bg9k0'></bdo><ul id='bg9k0'></ul>

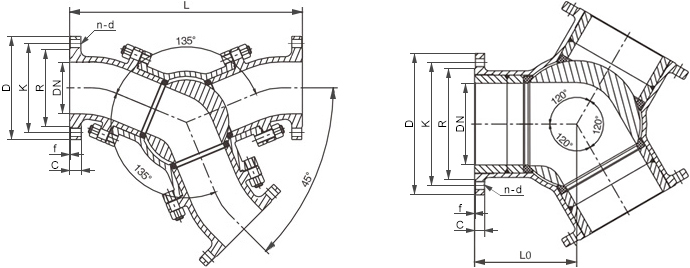

三通換向球閥由(you)L型(xing)(xing)、T型(xing)(xing)或Y型(xing)(xing)三(san)(san)通球閥與驅動(dong)(dong)(dong)(dong)裝(zhuang)置組成,適合(he)安裝(zhuang)在(zai)(zai)氣(qi)力(li)輸送系統(tong)中用(yong)(yong)以切(qie)換(huan)(huan)(huan)管道(dao)中粉(fen)體粉(fen)料(liao)(liao)、塑料(liao)(liao)顆粒(li)、粉(fen)粒(li)混(hun)合(he)料(liao)(liao)和片(pian)狀料(liao)(liao)等介質(zhi)流(liu)動(dong)(dong)(dong)(dong)方(fang)向,其(qi)三(san)(san)個(ge)通道(dao)呈角度布置,一般(ban)以中間端為(wei)(wei)入(ru)口(kou),左右兩(liang)端為(wei)(wei)出(chu)(chu)口(kou)。該(gai)閥通常(chang)采用(yong)(yong)氣(qi)缸(gang)為(wei)(wei)執行(xing)機構(gou),以壓縮空氣(qi)作(zuo)為(wei)(wei)動(dong)(dong)(dong)(dong)力(li)源(yuan),并經電(dian)磁(ci)閥與限位開關(guan)配(pei)合(he)使(shi)用(yong)(yong)來控制驅動(dong)(dong)(dong)(dong)裝(zhuang)置帶動(dong)(dong)(dong)(dong)球體在(zai)(zai)閥腔(qiang)內作(zuo)90°、180°或120°及135°角行(xing)程往復運(yun)動(dong)(dong)(dong)(dong),以實現自動(dong)(dong)(dong)(dong)換(huan)(huan)(huan)向的(de)(de)(de)功能,它通過電(dian)磁(ci)閥的(de)(de)(de)通電(dian)或斷電(dian)來切(qie)換(huan)(huan)(huan)輸入(ru)到氣(qi)缸(gang)的(de)(de)(de)氣(qi)源(yuan)進(jin)(jin)(jin)氣(qi)點進(jin)(jin)(jin)而(er)控制氣(qi)動(dong)(dong)(dong)(dong)執行(xing)器的(de)(de)(de)轉(zhuan)動(dong)(dong)(dong)(dong)方(fang)向,而(er)閥芯動(dong)(dong)(dong)(dong)作(zuo)的(de)(de)(de)兩(liang)個(ge)位置則由(you)安裝(zhuang)在(zai)(zai)氣(qi)動(dong)(dong)(dong)(dong)執行(xing)器上面的(de)(de)(de)限位開關(guan)進(jin)(jin)(jin)行(xing)檢(jian)測,閥正常(chang)工(gong)作(zuo)時(shi),閥芯轉(zhuan)到一個(ge)位置,右出(chu)(chu)料(liao)(liao)口(kou)關(guan)上,進(jin)(jin)(jin)料(liao)(liao)從左出(chu)(chu)料(liao)(liao)口(kou)出(chu)(chu)去,當(dang)換(huan)(huan)(huan)向指(zhi)令發(fa)出(chu)(chu)后,閥芯轉(zhuan)到另一個(ge)位置,關(guan)閉左出(chu)(chu)料(liao)(liao)口(kou),進(jin)(jin)(jin)料(liao)(liao)從右出(chu)(chu)料(liao)(liao)口(kou)出(chu)(chu)去,從而(er)使(shi)閥門的(de)(de)(de)流(liu)向切(qie)換(huan)(huan)(huan)達到了自動(dong)(dong)(dong)(dong)化(hua)控制。本產品閥體和主(zhu)要部件均為(wei)(wei)整體鑄造成型(xing)(xing),構(gou)造堅(jian)固,強度高不易變(bian)形,尤其(qi)Y形流(liu)道(dao)結構(gou)形式設(she)計,使(shi)物(wu)料(liao)(liao)通過時(shi)順(shun)暢(chang),流(liu)阻力(li)小(xiao),不會形成堵塞(sai)。

| 序號 | 部件名稱 | 材料名稱 | ||||

| 1 | 閥 蓋 | WCB | CF8 | CF3 | CF8M | CF3M |

| 2 | 閥 體 | WCB | CF8 | CF3 | CF8M | CF3M |

| 3 | 閥 座 | R-PTFE、PTFE、TEFLON、NYLON、PPL、PEEK、DEVLON、不銹鋼+硬質合金 | ||||

| 4 | 球 體 | CF8 | CF8 | CF3 | CF8M | CF3M |

| 5 | 閥 桿 | CF8 | CF8 | CF3 | CF8M | CF3M |

| 6 | 填 料 | GRAPHITE、R-PTFE、PTFE、TEFLON、PCTFE | ||||

| 7 | 填料壓蓋 | WCB | CF8 | CF3 | CF8M | CF3M |

| 8 | 下 端 蓋 | WCB | CF8 | CF3 | CF8M | CF3M |

| 公稱壓力PN(MPa) | 0.6 | 1.0 | 1.6 | 2.5 | 2.0 |

| 殼體試驗壓力(MPa) | 0.9 | 1.5 | 2.4 | 3.75 | 3.0 |

| 高壓液體密封試驗壓力(MPa) | 0.66 | 1.1 | 1.76 | 2.75 | 2.2 |

| 低壓氣體密封試驗壓力(MPa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| 設計制造 | GB/T 12237、GB/T 21385、API 608、ASME B16.34 | ||||

| 結構長度 | 按本廠標準Q/CB的規定或按訂貨合同要求 | ||||

| 連接法蘭 | JB/T 79、GB/T 9113、HG/T 20592、HG/T 20615、SH/T 3406、ASME B16.5等 | ||||

| 檢驗試驗 | GB/T 26480、JB/T 9092、API 598 | ||||

| 公稱壓力 PN | 公稱通徑 DN | 外形及連接尺寸/mm | ||||||

| L | L0 | D | K | R | C-f | n-d | ||

| 16 | 40 | 310 | 110 | 150 | 110 | 88 | 18-2 | 4-?18 |

| 50 | 340 | 110 | 165 | 125 | 102 | 18-2 | 4-?18 | |

| 65 | 400 | 130 | 185 | 145 | 122 | 18-2 | 8-?18 | |

| 80 | 410 | 150 | 200 | 160 | 138 | 20-2 | 8-?18 | |

| 100 | 460 | 170 | 220 | 180 | 158 | 20-2 | 8-?18 | |

| 125 | 560 | 190 | 250 | 210 | 188 | 22-2 | 8-?18 | |

| 150 | 660 | 210 | 285 | 240 | 212 | 22-2 | 8-?22 | |

| 200 | 800 | 235 | 340 | 295 | 268 | 24-2 | 12-?22 | |

| 250 | 1030 | 290 | 405 | 355 | 320 | 26-2 | 12-?26 | |

| 300 | 1140 | 350 | 460 | 410 | 378 | 28-2 | 12-?26 | |

| 350 | 1257 | — | 520 | 470 | 428 | 30-2 | 16-?26 | |

| 表中未列出的其他規格尺寸,請咨詢汗越閥門技術部! | ||||||||

本產品可根據工況需要,將兩出口端之間的夾角設計成30°、45°、60°、90°、120°及其他角度等,可配置手柄、蝸輪蝸桿傳動、氣動、電動,液動等。如果你需訂購我廠三通球閥系(xi)列(lie)產品(pin),請(qing)注明公(gong)(gong)稱尺寸、公(gong)(gong)稱壓力、閥體和(he)內(nei)件材料、流(liu)道角(jiao)度、使(shi)用(yong)溫度、法蘭標準及密(mi)封面(mian)形(xing)式等。