<bdo id='kjddy'></bdo><ul id='kjddy'></ul>

T型三通球閥的(de)球(qiu)體(ti)(ti)(ti)與閥體(ti)(ti)(ti)的(de)通(tong)(tong)(tong)(tong)(tong)道(dao)(dao)形(xing)狀一樣呈T字形(xing)垂直(zhi)布(bu)置,其(qi)球(qiu)體(ti)(ti)(ti)不但連(lian)(lian)通(tong)(tong)(tong)(tong)(tong)了(le)兩(liang)個垂直(zhi)交叉成90度方(fang)向的(de)流(liu)(liu)體(ti)(ti)(ti)通(tong)(tong)(tong)(tong)(tong)道(dao)(dao),而且其(qi)中一條的(de)孔道(dao)(dao)完(wan)全打通(tong)(tong)(tong)(tong)(tong),可(ke)(ke)以(yi)(yi)同時連(lian)(lian)接三(san)個流(liu)(liu)道(dao)(dao),形(xing)狀呈T型(xing)。該(gai)閥主要用(yong)于(yu)管路中介(jie)質(zhi)的(de)分流(liu)(liu)、合流(liu)(liu)及流(liu)(liu)向的(de)切(qie)換,可(ke)(ke)以(yi)(yi)使三(san)個通(tong)(tong)(tong)(tong)(tong)道(dao)(dao)相互連(lian)(lian)通(tong)(tong)(tong)(tong)(tong)或使其(qi)中兩(liang)個通(tong)(tong)(tong)(tong)(tong)道(dao)(dao)連(lian)(lian)通(tong)(tong)(tong)(tong)(tong)。本產品可(ke)(ke)替(ti)(ti)代(dai)L型(xing)三(san)通(tong)(tong)(tong)(tong)(tong)球(qiu)閥,當替(ti)(ti)代(dai)L形(xing)用(yong)于(yu)切(qie)換介(jie)質(zhi)時,兩(liang)側中任一通(tong)(tong)(tong)(tong)(tong)道(dao)(dao)可(ke)(ke)作為公共(gong)端,連(lian)(lian)接其(qi)它通(tong)(tong)(tong)(tong)(tong)道(dao)(dao),相對(dui)于(yu)L型(xing)的(de)只有中心(xin)的(de)通(tong)(tong)(tong)(tong)(tong)道(dao)(dao)可(ke)(ke)作為公共(gong)端,T型(xing)在方(fang)向上(shang)的(de)選擇更(geng)方(fang)便,更(geng)具有靈活多樣性。

T型三(san)(san)通球(qiu)閥通常采用(yong)(yong)三(san)(san)閥座(zuo)密封(feng)結構(gou),亦(yi)可根據(ju)用(yong)(yong)戶(hu)要(yao)求設計成(cheng)四閥座(zuo),其不僅能實現對介質(zhi)流(liu)(liu)向的(de)(de)切換,也可使(shi)三(san)(san)個通道相(xiang)互連通,同時(shi)也可關閉任一(yi)通道,使(shi)另外兩個流(liu)(liu)道接通,靈活控制管路中(zhong)介質(zhi)的(de)(de)合流(liu)(liu)或分流(liu)(liu)。該閥可以(yi)減少系統(tong)中(zhong)閥門及管配件的(de)(de)使(shi)用(yong)(yong)數(shu)量(liang),節省(sheng)了空間的(de)(de)同時(shi),簡(jian)化了操(cao)(cao)作,大大降低誤操(cao)(cao)作的(de)(de)可能性,有(you)效(xiao)降低成(cheng)本。本產品有(you)多種驅(qu)動方(fang)式(shi)供用(yong)(yong)戶(hu)選擇,主要(yao)有(you)手(shou)動、蝸輪蝸桿(gan)傳動、氣動、電動,液動等,特(te)適(shi)用(yong)(yong)于液體、氣體、粉(fen)塵(chen)、漿(jiang)料及含固體顆粒等介質(zhi)。

| 序號 | 部件名稱 | 材料名稱 | ||||

| 1 | 閥 體 | WCB | CF8 | CF3 | CF8M | CF3M |

| 2 | 閥 蓋 | WCB | CF8 | CF3 | CF8M | CF3M |

| 3 | 閥 座 | R-PTFE、PTFE、TEFLON、NYLON、PPL、PEEK、DEVLON、不銹鋼+硬質合金 | ||||

| 4 | 球 體 | 2Cr13 | 304 | 304L | 316 | 316L |

| 5 | 閥 桿 | 2Cr13 | 304 | 304L | 316 | 316L |

| 6 | 填 料 | GRAPHITE、R-PTFE、PTFE、TEFLON、PCTFE | ||||

| 7 | 螺 栓 | 35CrMo | 304 | 304 | 316 | 316 |

| 8 | 螺 母 | 30CrMo | 304 | 304 | 316 | 316 |

| 公稱壓力PN(MPa) | 1.6 | 2.5 | 4.0 | 6.3 | 10.0 |

| 殼體試驗壓力(MPa) | 2.4 | 3.75 | 6.0 | 9.45 | 15.0 |

| 高壓液體密封試驗壓力(MPa) | 1.76 | 2.75 | 4.4 | 6.93 | 11.0 |

| 低壓氣體密封試驗壓力(MPa) | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 | 0.4~0.7 |

| 設計制造 | GB/T 12237、GB/T 21385、API 608、ASME B16.34 | ||||

| 結構長度 | 按本廠標準Q/CB的規定或按訂貨合同要求 | ||||

| 連接法蘭 | JB/T 79、GB/T 9113、HG/T 20592、HG/T 20615、SH/T 3406、ASME B16.5等 | ||||

| 檢驗試驗 | GB/T 26480、JB/T 9092、API 598 | ||||

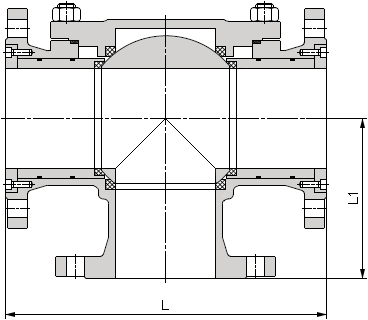

| 公稱壓力 PN | 公稱通徑 DN | 結構尺寸/mm | 公稱壓力 PN | 公稱通徑 DN | 結構尺寸/mm | ||

| L | L1 | L | L1 | ||||

| 16 | 25 | 180 | 90 | 16 | 100 | 320 | 160 |

| 32 | 200 | 100 | 125 | 380 | 190 | ||

| 40 | 220 | 110 | 150 | 440 | 220 | ||

| 50 | 240 | 120 | 200 | 550 | 275 | ||

| 65 | 260 | 130 | 250 | 670 | 335 | ||

| 80 | 280 | 140 | 300 | 720 | 425 | ||

| 表中未列出的其他規格尺寸,請咨詢汗越閥門技術部! | |||||||

如果你需訂購我廠三通球閥系列產品,咨詢時(shi)煩請(qing)注明公稱(cheng)通(tong)徑、公稱(cheng)壓力(li)、閥(fa)(fa)(fa)體和內(nei)件材(cai)料、工作介質、使(shi)用(yong)溫度、法蘭標準及密封面型(xing)式等。本產品當采用(yong)四閥(fa)(fa)(fa)座設計時(shi),可以使(shi)同一個(ge)閥(fa)(fa)(fa)門(men)既(ji)可以控制不同流(liu)向,又具有開關閥(fa)(fa)(fa)的功(gong)能,并且閥(fa)(fa)(fa)的功(gong)能切換簡(jian)單(dan),只要通(tong)過閥(fa)(fa)(fa)桿的旋(xuan)轉即(ji)可實(shi)現。