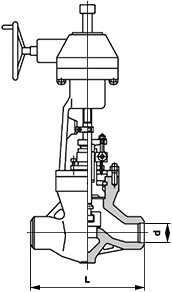

高溫高壓電站截止閥是一種(zhong)適(shi)用于公稱壓(ya)(ya)(ya)(ya)力(li)(li)PN為(wei)20、25、32MPa,工(gong)(gong)作(zuo)溫(wen)度(du)等于或低于425℃或工(gong)(gong)作(zuo)壓(ya)(ya)(ya)(ya)力(li)(li)p為(wei)10、14、17MPa,工(gong)(gong)作(zuo)溫(wen)度(du)為(wei)510、540、570℃,工(gong)(gong)作(zuo)介(jie)質(zhi)為(wei)水、蒸汽(qi)的截止閥(fa),其(qi)通過閥(fa)桿做旋(xuan)(xuan)轉(zhuan)升降運動(dong),來(lai)實(shi)現管路介(jie)質(zhi)的接通或切斷(duan),當順時(shi)(shi)針方向旋(xuan)(xuan)轉(zhuan)手輪時(shi)(shi),閥(fa)桿螺紋下(xia)旋(xuan)(xuan),閥(fa)瓣密(mi)(mi)(mi)封面(mian)(mian)與閥(fa)座密(mi)(mi)(mi)封面(mian)(mian)緊密(mi)(mi)(mi)接觸,閥(fa)處于關閉狀態,當逆時(shi)(shi)針方向旋(xuan)(xuan)轉(zhuan)手輪時(shi)(shi),閥(fa)桿螺紋上旋(xuan)(xuan),閥(fa)瓣密(mi)(mi)(mi)封面(mian)(mian)與閥(fa)座密(mi)(mi)(mi)封面(mian)(mian)脫開,閥(fa)開啟。該閥(fa)中(zhong)腔通常采用壓(ya)(ya)(ya)(ya)力(li)(li)自密(mi)(mi)(mi)封結構(gou),密(mi)(mi)(mi)封環為(wei)S軟鋼(gang),30°錐(zhui)角設計,有(you)利于變形(xing),在介(jie)質(zhi)壓(ya)(ya)(ya)(ya)力(li)(li)作(zuo)用下(xia)閥(fa)蓋向上移動(dong),密(mi)(mi)(mi)封環在閥(fa)體與閥(fa)蓋錐(zhui)面(mian)(mian)之間受擠壓(ya)(ya)(ya)(ya),產生(sheng)變形(xing),阻止介(jie)質(zhi)外泄,介(jie)質(zhi)壓(ya)(ya)(ya)(ya)力(li)(li)越高,密(mi)(mi)(mi)封力(li)(li)越大。本(ben)產品特適(shi)合安裝在火力(li)(li)發電(dian)站(zhan)水、汽(qi)管道上,作(zuo)啟閉裝置(zhi)用。

| 序號 | 部件名稱 | 材料名稱 | |||||

| 1 | 閥 體 | A216 WCB | A217 WC6 | A217 WC9 | ZG20CrMo | ZG20CrMoV | ZG15Cr1Mo1V |

| 2 | 閥 座 | A105 | A182 F11 | A182 F22 | 15CrMo | 12Cr1MoV | 15Cr1Mo1V |

| 3 | 閥 瓣 | A105 | A182 F11 | A182 F22 | 15CrMo | 12Cr1MoV | 15Cr1Mo1V |

| 4 | 閥 桿 | A182 F6a CL.2 | A182 F11 | A182 F22 | 25Cr2MoVA | 20Cr1Mo1V1A | 20Cr1Mo1V1A |

| 5 | 閥 蓋 | A216 WCB | A217 WC6 | A217 WC9 | ZG20CrMo | ZG20CrMoV | ZG15Cr1Mo1V |

| 6 | 密 封 圈 | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE |

| 7 | 四 開 環 | A182 F6a CL.2 | A182 F11 | A182 F22 | 15CrMo | 12Cr1MoV | 15Cr1Mo1V |

| 8 | 填 料 | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE | GRAPHITE |

| 9 | 填料壓板 | A216 WCB | A217 WC6 | A217 WC9 | ZG20CrMo | ZG20CrMoV | ZG15Cr1Mo1V |

| 公稱壓力PN(MPa) | 20.0 | 25.0 | 32.0 | — | — | — |

| 工作壓力(MPa) | — | — | — | 10.0 | 14.0 | 17.0 |

| 工作溫度(℃) | — | — | — | 540 | 540 | 540 |

| 殼體水壓試驗壓力(MPa) | 30.0 | 37.5 | 48.0 | 30.0 | 40.0 | 48.0 |

| 倒密封水壓試驗壓力(MPa) | 22.0 | 27.5 | 35.2 | 12.5 | 17.5 | 21.3 |

| 密封水壓試驗壓力(MPa) | 22.0 | 27.5 | 35.2 | 12.5 | 17.5 | 21.3 |

| 設計制造 | NB/T 47044、DL/T 531、ASME B16.34、JIS E-101 | |||||

| 結構長度 | GB/T 12221、ASME B16.10、JIS E-101 | |||||

| 焊接坡口 | NB/T 47044、DL/T 531、ASME B16.25或按訂貨合同要求 | |||||

| 檢驗試驗 | NB/T 47044、DL/T 531、API 598、JIS E-101 | |||||

| 公稱壓力 PN | 公稱尺寸 DN | 外形尺寸/mm | 公稱壓力 PN | 公稱尺寸 DN | 外形尺寸/mm | ||

| d | L | d | L | ||||

| 250 | 10 | 10 | 120 | 320 | 10 | 10 | 120 |

| 20 | 19 | 170 | 20 | 19 | 170 | ||

| 25 | 22 | 170 | 25 | 22 | 170 | ||

| 32 | 26 | 170 | 32 | 26 | 170 | ||

| 40 | 36 | 250 | 40 | 36 | 250 | ||

| 50 | 42 | 250 | 50 | 42 | 250 | ||

| 65 | 56 | 340 | 65 | 60 | 470 | ||

| 80 | 64 | 390 | 80 | 80 | 570 | ||

| 100 | 84 | 480 | 100 | 96 | 660 | ||

| 表中未列出的其他規格參數,請咨詢汗越閥門技術部! | |||||||